News

Environmental & Economic Impacts of Combusting Biogas in Microturbine Engines

Microturbine engines are smaller versions of gas turbine engines ranging from 30 kilowatt to 333 kilowatt for individual engines to several megawatts when multiple engines are combined. The efficiency of converting biogas to electricity ranges from around 22-27%. Nitrogen oxide emissions from microturbine engines powered by biogas fuel typically tend to be less than 9 parts per million by volume (ppmv).

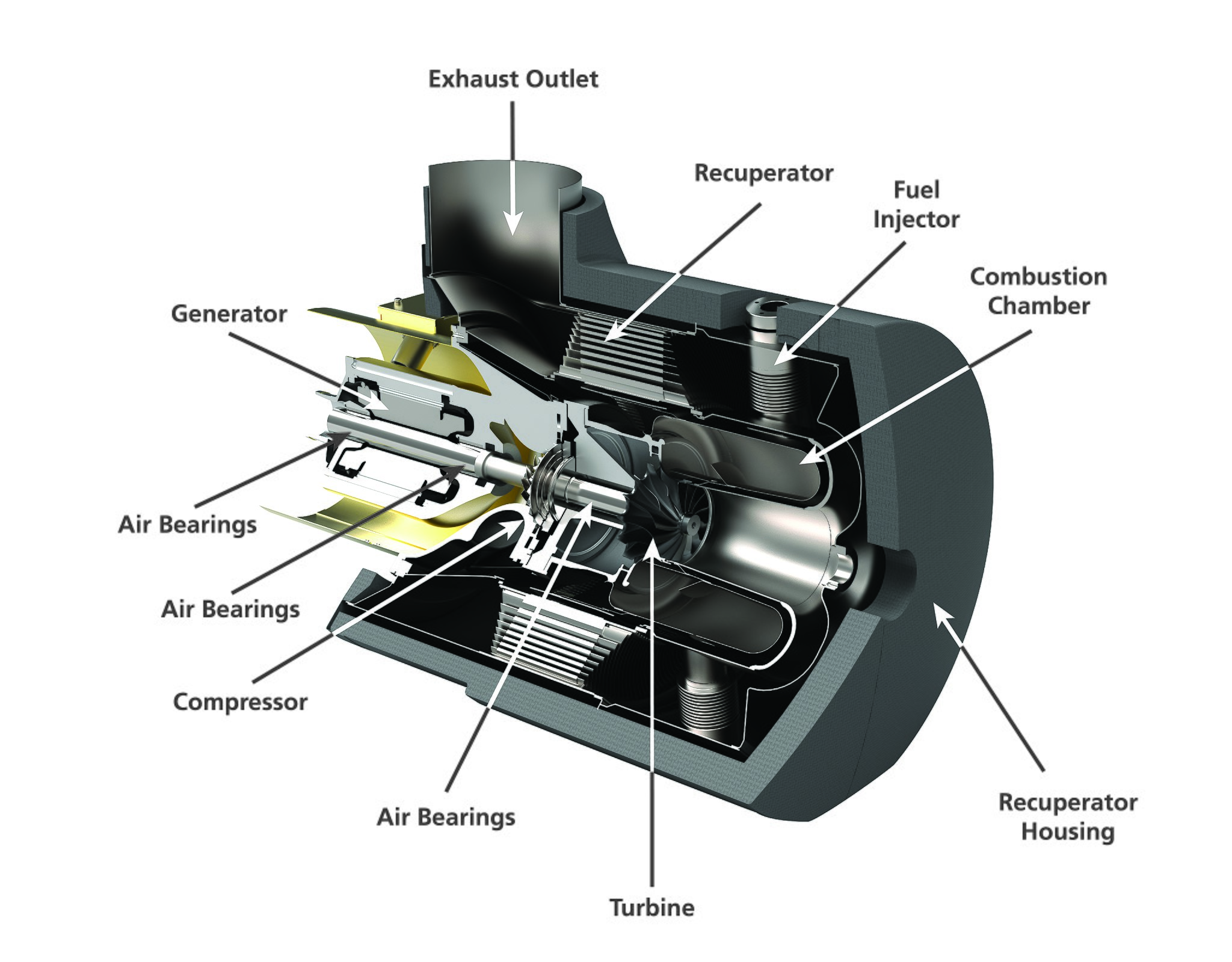

Like their larger gas turbine counterparts, microturbine engines operate on the Brayton Cycle, where incoming air is compressed before biogas (or liquid) fuel is injected into the mix which is then combusted in the combustor. The hot combustion gas, which is under high pressure, expands and passes through a turbine which generates shaft power from the mechanic rotating action of the turbines that runs the compressor and the electric generator.

Efficiency of Microturbine Engines

According to the EPA report, Evaluating the Air Quality, Climate & Economic Impacts of Biogas Management Technologies, the efficiency of converting biogas into electricity using microturbine engines fitted with recuperators powered by biogas ranges from around 22-27%

Electrical conversion efficiencies for microturbines (with recuperators) fueled on biogas range from about 22% to 27% [based on a higher heating value and ambient air temperature of 60 °F]. Table 3 displays nominal electrical conversion efficiencies and corresponding gas energy input flows for typical microturbines.

Input energy ranges from around 0.47 million international British thermal units per hour (MMBtu/hour) for a 30 kilowatt microturbine engine to 4.2 MMBtu/hour for a 333 kilowatt microturbine engine, while energy conversion efficiency ranges from 15,700 Btu/kWh to 12,600 Btu/kWh for a 30 kilowatt and 333 kilowatt microturbine respectively (see table 3 on page 9 of the EPA report). Energy conversion efficiency and energy production decreases as ambient temperatures rise or site elevation increases as there is less oxygen available at higher elevations for combustion.

Emissions from Biogas Powered Microturbine Engines

Criteria Pollutants

Uncontrolled pollutant emissions stemming from biogas powered microturbine engines tend to range from between 3-9 parts per million (ppm) for nitrogen oxides, carbon monoxide, and volatile organic compounds. Source tests for biogas powered micro-turbine engines conducted in the Bay Area Air Quality Management District and South Coast Air Quality Management District in California showed that average nitrogen oxide emissions from 250 kW microturbine engines designed with no exhaust reduction control measures were around 4.2ppm (see Table 4 on page 10 and Figure 7 on page 11 of the EPA report for a more detailed analysis of output-based emissions produced by biogas powered microturbine engines).

Before 2013, a number of biogas powered microturbine engines met distributed generation emission standards set by the California Air Resources Board (CARB) — 0.5 lb/MWh for nitrogen oxides, 6 lb/MWh for carbon monoxide and 1 lb/MWh for volatile organic carbons. However, as the distributed generation emission standards for biogas powered devices, including microturbine engines, became stricter after January 2013, there currently are no biogas powered devices that meet these increased standards. Biogas powered engines can still be permitted via local air districts if they meet local regulations and emission limits.

Green House Gas Emissions

Emission factors for greenhouse gases produced by microturbine engines are as follows: the average greenhouse gas emission factor for methane is 0.167lbs CH4/MMBtu, while the average GHG emission factor for carbon dioxide is 191.3 lbs CO2/MMBtu, and the average nitrous oxide emission factor is 0.00026 lbs N2O/MMBtu.

Based on the emission factors above together with engine conversion efficiencies and the global warming potential over 100 years (GWP100) of the greenhouse gas in question, the output-based greenhouse gas emissions (carbon dioxide equivalent) of methane for microturbine engines is estimated to range from 88.8 lb CO2eq/MWh (for a 30 kW operation) to 71.7 lb CO2eq/MWh (333 kW operation). The greenhouse gas emissions of biogenic carbon dioxide is estimated to range from 3,000 lb CO2eq/MWh (for a 30 kW operation) to 2,420 lb CO2eq/MWh (333 kW operation). The greenhouse gas emissions of nitrous oxide is estimated to range from 1.19 lb CO2eq/MWh (for a 30 kW operation) to 0.96 lb CO2eq/MWh (333 kW operation).

Costs Associated with Microturbine Engines

Installation costs of micro-turbine engines range from over $6,800/kW for a 30 kW microturbine engine to around $3,610/kW for a 333 kW micro-turbine engine. Estimated levelized cost of energy ranges from $126 per Mega Watt hour to $64 per Mega Watt hour for 30 kW and 333 kW units respectively.

Featured Image by Calebfinch, CC BY-SA 4.0, via Wikimedia Commons