Gas Analyzers

Filters

-

Save 0%

Save %

Original price $3,540.00 - Original price $3,540.00Original price$3,540.00$3,540.00 - $3,540.00Current price $3,540.00| /

Save 0%

Save %

Original price $3,540.00 - Original price $3,540.00Original price$3,540.00$3,540.00 - $3,540.00Current price $3,540.00| /CO2 Analyzer - Viasensor G110-00L CO2 0-100%

* OPERATIONS MANUAL * * G110 INFO SHEET * Description 0-100% CO2 Analyzer for specialist controlled atmosphere monitoring (G110-00L) CO2 analyze...

View full detailsOriginal price $3,540.00 - Original price $3,540.00Original price$3,540.00$3,540.00 - $3,540.00Current price $3,540.00| /Save 0% Save % -

Save up to 0%

Save %

Original price $2,722.00 - Original price $6,273.00Original price$2,722.00 - $6,273.00$2,722.00 - $6,273.00Current price $2,722.00| /

Save up to 0%

Save %

Original price $2,722.00 - Original price $6,273.00Original price$2,722.00 - $6,273.00$2,722.00 - $6,273.00Current price $2,722.00| /MRU AMPRO PLUS - Handheld Combustion Gas Analyzer

* OPERATIONS MANUAL * * AMPRO PLUS INFO SHEET * * APP INFO * * EXPORTING DATA * * LEAK TESTING * * FIRMWARE UPDATE * * SENSOR ADJUSTMENT * Descript...

View full detailsOriginal price $2,722.00 - Original price $6,273.00Original price$2,722.00 - $6,273.00$2,722.00 - $6,273.00Current price $2,722.00| /Save up to 0% Save % -

Save 0%

Save %

Save 0%

Save %

MRU Varioluxx Portable Emission Analyzer

* VARIOLUXX BROCHURE * Description About the Manufacturer MRU is a German company making extremely well-engineered emission monitoring systems. Th...

View full detailsSave 0% Save % -

Save 0%

Save %

Original price $7,961.00 - Original price $7,961.00Original price$7,961.00$7,961.00 - $7,961.00Current price $7,961.00| /

Save 0%

Save %

Original price $7,961.00 - Original price $7,961.00Original price$7,961.00$7,961.00 - $7,961.00Current price $7,961.00| /MRU NOVA Plus - Engine Emissions Analyzer

* DATA SHEET * Description MRU Nova Plus emission analyzer is a versatile biogas analyzer that is also used in engine emissions tuning and compli...

View full detailsOriginal price $7,961.00 - Original price $7,961.00Original price$7,961.00$7,961.00 - $7,961.00Current price $7,961.00| /Save 0% Save % -

Save 0%

Save %

Save 0%

Save %

In Situ O2 & COe Analyzer - MRU OMS 420 RT

Description About the manufacturer MRU is a German company making extremely well-engineered emission monitoring systems. Their products are very ...

View full detailsSave 0% Save % -

Save 0%

Save %

Save 0%

Save %

High Temp O2 & COe Analyzer - MRU OMS 420 HT

Description About the manufacturer MRU is a German company making extremely well-engineered emission monitoring systems. Their products are very ...

View full detailsSave 0% Save % -

Save 0%

Save %

Save 0%

Save %

High End Flue Gas Emission Analyzer - MGA Prime

* MGA PRIME BROCHURE * * MGA PRIME QUESTIONNAIRE * Description -Precise and very stable offset measuring technique using special non dispersive i...

View full detailsSave 0% Save % -

Save 0%

Save %

Save 0%

Save %

Hazardous Environment O2 & COe Monitor - MRU OMS 420 EX

* USER MANUAL * Description About the manufacturer MRU is a German company making extremely well-engineered emission monitoring systems. Their pr...

View full detailsSave 0% Save % -

Save 0%

Save %

Save 0%

Save %

Fixed Extractive Gas Analyzer - MRU SWG 300-1

Key Specifications Benefits & Applications Additional Info Models FAQ PDF About the manufacturer MRU is a German company making extremel...

View full detailsSave 0% Save % -

Save 0%

Save %

Original price $10,233.00 - Original price $10,233.00Original price$10,233.00$10,233.00 - $10,233.00Current price $10,233.00| /

Save 0%

Save %

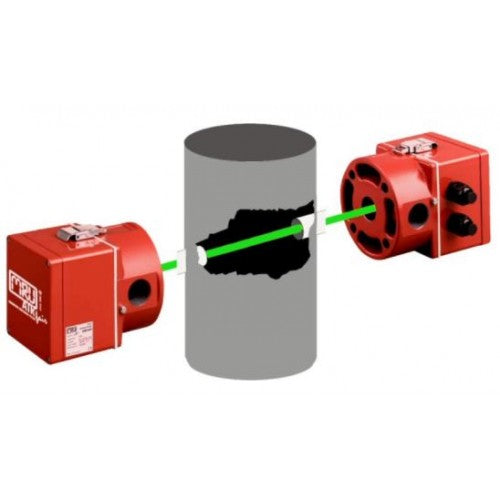

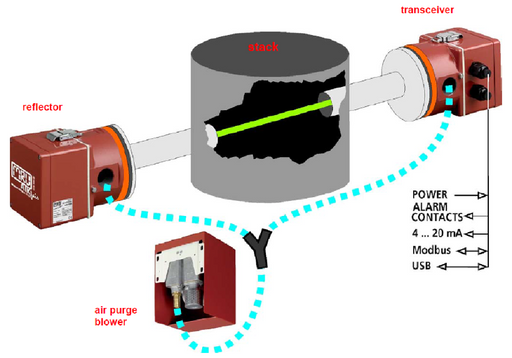

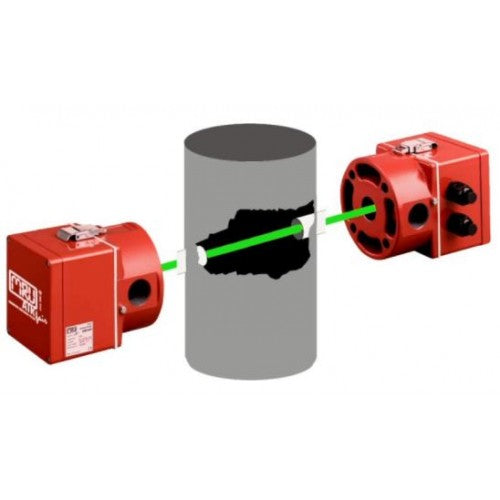

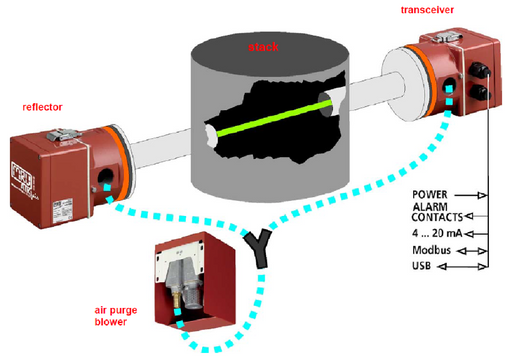

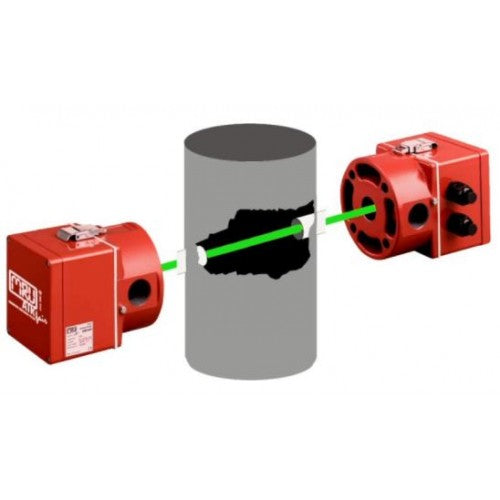

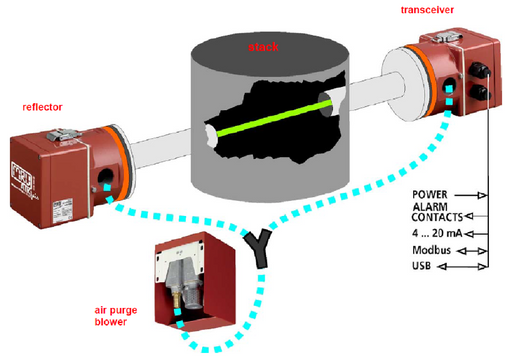

Original price $10,233.00 - Original price $10,233.00Original price$10,233.00$10,233.00 - $10,233.00Current price $10,233.00| /Dust Opacity Monitor - MRU DM 401 (short)

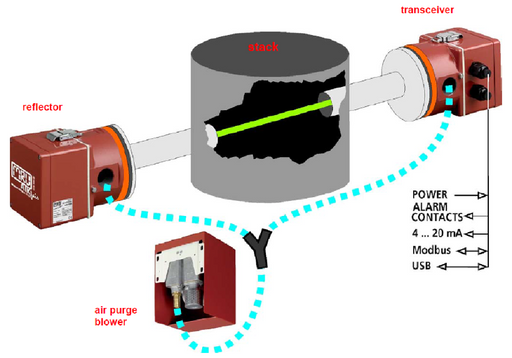

* DM 401 BROCHURE * Description The dust opacity monitoring system has following major parts: • double pass opacity monitor (transceiver and re...

View full detailsOriginal price $10,233.00 - Original price $10,233.00Original price$10,233.00$10,233.00 - $10,233.00Current price $10,233.00| /Save 0% Save % -

Save 0%

Save %

Original price $4,689.00 - Original price $4,689.00Original price$4,689.00$4,689.00 - $4,689.00Current price $4,689.00| /

Save 0%

Save %

Original price $4,689.00 - Original price $4,689.00Original price$4,689.00$4,689.00 - $4,689.00Current price $4,689.00| /Compact Combustion Gas Analyzer - MRU NOVA Compact

Description About the manufacturer MRU is a German company making extremely well-engineered emission monitoring systems. Their products are very ...

View full detailsOriginal price $4,689.00 - Original price $4,689.00Original price$4,689.00$4,689.00 - $4,689.00Current price $4,689.00| /Save 0% Save % -

Save 0%

Save %

Original price $3,770.00 - Original price $3,770.00Original price$3,770.00$3,770.00 - $3,770.00Current price $3,770.00| /

Save 0%

Save %

Original price $3,770.00 - Original price $3,770.00Original price$3,770.00$3,770.00 - $3,770.00Current price $3,770.00| /Indoor Air Quality Meter - Viasensor G150-10L CO2 0-10,000 PPM + O2

* OPERATIONS MANUAL * * G150 INFO SHEET * Description IAQ analyzer package 0-10,000ppm CO2 + 100% O2 with internal pump. CO2 analyzer designed to ...

View full detailsOriginal price $3,770.00 - Original price $3,770.00Original price$3,770.00$3,770.00 - $3,770.00Current price $3,770.00| /Save 0% Save % -

Save 0%

Save %

Original price $4,220.00 - Original price $4,220.00Original price$4,220.00$4,220.00 - $4,220.00Current price $4,220.00| /

Save 0%

Save %

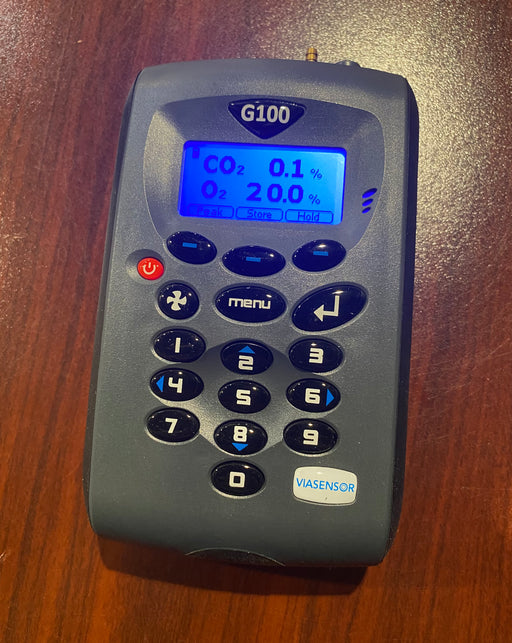

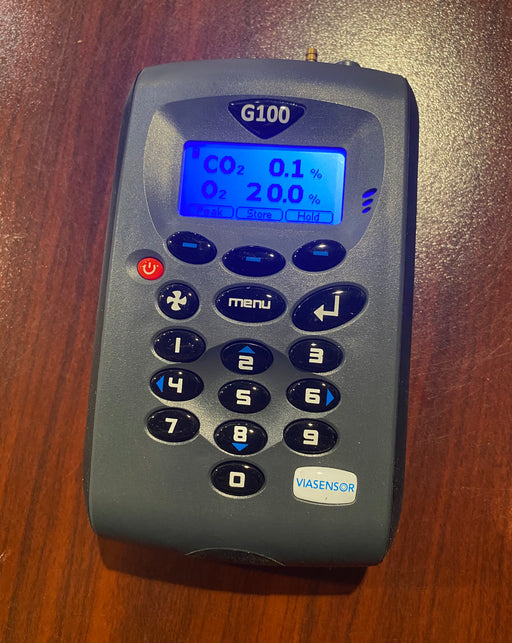

Original price $4,220.00 - Original price $4,220.00Original price$4,220.00$4,220.00 - $4,220.00Current price $4,220.00| /Incubator Analyzer - Viasensor G100-10PKG CO2 0-20% + O2

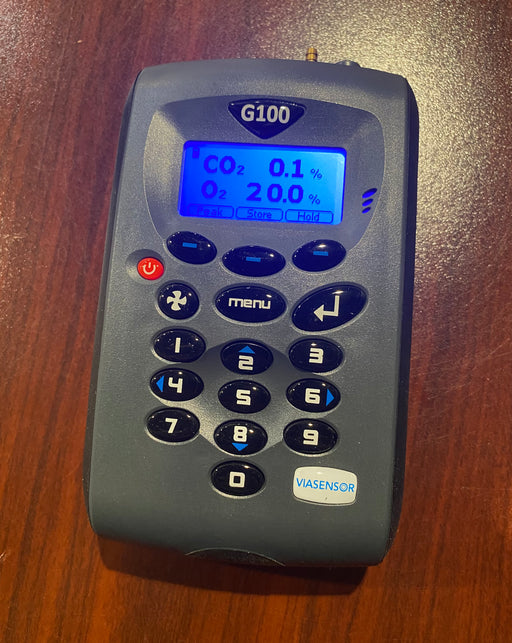

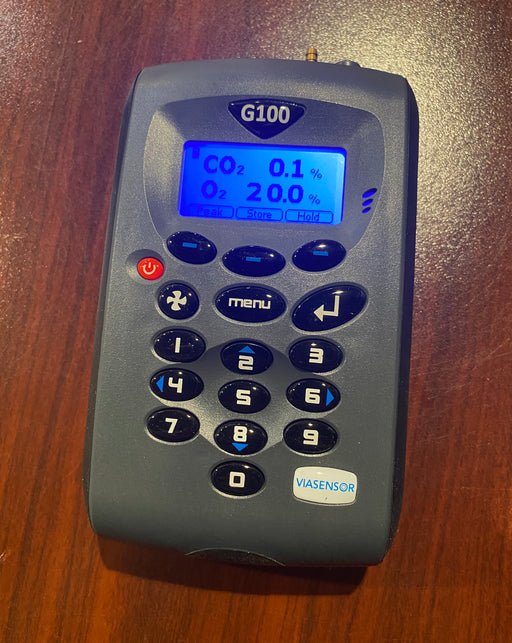

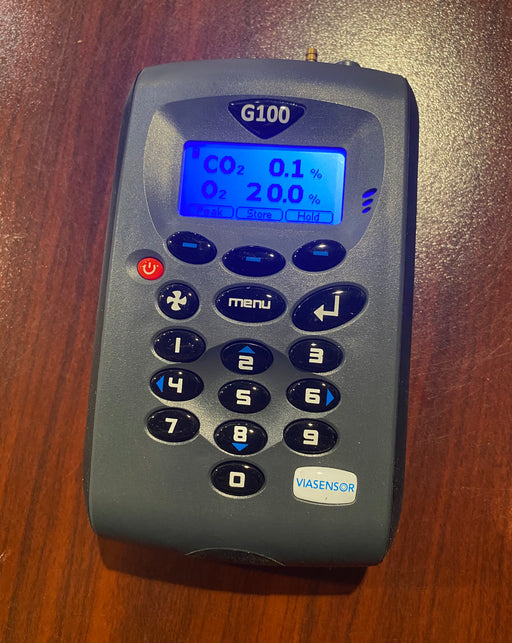

* OPERATIONS MANUAL * * G100 INFO SHEET * Description Viasensor G100-10PKG This unit has been developed to incorporate the latest technology and ...

View full detailsOriginal price $4,220.00 - Original price $4,220.00Original price$4,220.00$4,220.00 - $4,220.00Current price $4,220.00| /Save 0% Save % -

Save 0%

Save %

Original price $5,210.00 - Original price $5,210.00Original price$5,210.00$5,210.00 - $5,210.00Current price $5,210.00| /

Save 0%

Save %

Original price $5,210.00 - Original price $5,210.00Original price$5,210.00$5,210.00 - $5,210.00Current price $5,210.00| /Incubator Analyzer - Viasensor G100-11L CO2 0-20% + O2 + RH

* OPERATIONS MANUAL * * G100 INFO SHEET * Description Incubator analyzer package 0-20% CO2 + 100% O2 with internal pump and G1.8 RH probe. CO2 an...

View full detailsOriginal price $5,210.00 - Original price $5,210.00Original price$5,210.00$5,210.00 - $5,210.00Current price $5,210.00| /Save 0% Save % -

Save 0%

Save %

Original price $5,100.00 - Original price $5,100.00Original price$5,100.00$5,100.00 - $5,100.00Current price $5,100.00| /

Save 0%

Save %

Original price $5,100.00 - Original price $5,100.00Original price$5,100.00$5,100.00 - $5,100.00Current price $5,100.00| /Indoor Air Quality Meter - Viasensor G150-11L CO2 0-10,000 PPM + O2 + RH

* OPERATIONS MANUAL * * G150 INFO SHEET * Description IAQ analyzer package 0-10,000 CO2 + 100% O2 with internal pump and G1.8 RH probe.CO2 analyze...

View full detailsOriginal price $5,100.00 - Original price $5,100.00Original price$5,100.00$5,100.00 - $5,100.00Current price $5,100.00| /Save 0% Save % -

Save 0%

Save %

Original price $3,710.00 - Original price $3,710.00Original price$3,710.00$3,710.00 - $3,710.00Current price $3,710.00| /

Save 0%

Save %

Original price $3,710.00 - Original price $3,710.00Original price$3,710.00$3,710.00 - $3,710.00Current price $3,710.00| /Incubator Analyzer - Viasensor G100-00PKG CO2 0-20%

* OPERATIONS MANUAL * * G100 INFO SHEET * Description Viasensor G100 Incubator CO2 Analyzer specifically designed to monitor CO2 for The verificat...

View full detailsOriginal price $3,710.00 - Original price $3,710.00Original price$3,710.00$3,710.00 - $3,710.00Current price $3,710.00| /Save 0% Save % -

Save 0%

Save %

Original price $4,810.00 - Original price $4,810.00Original price$4,810.00$4,810.00 - $4,810.00Current price $4,810.00| /

Save 0%

Save %

Original price $4,810.00 - Original price $4,810.00Original price$4,810.00$4,810.00 - $4,810.00Current price $4,810.00| /Incubator Analyzer - Viasensor G100-01L CO2 0-20% + RH

* OPERATIONS MANUAL * * G100 INFO SHEET * Description Incubator analyzer package 0-20% CO2 with internal pump and G1.8 RH probe.CO2 analyzer speci...

View full detailsOriginal price $4,810.00 - Original price $4,810.00Original price$4,810.00$4,810.00 - $4,810.00Current price $4,810.00| /Save 0% Save % -

Save 0%

Save %

Original price $9,440.00 - Original price $9,440.00Original price$9,440.00$9,440.00 - $9,440.00Current price $9,440.00| /

Save 0%

Save %

Original price $9,440.00 - Original price $9,440.00Original price$9,440.00$9,440.00 - $9,440.00Current price $9,440.00| /Medical Analyzer - Viasensor G210-11PKG N2O 0-100% + O2 + CO + CO2

* OPERATIONS MANUAL * * G210 INFO SHEET * * QUICK START GUIDE * Description Viasensor G210-11PKG OVERVIEWThe G210-11PKG is designed for measureme...

View full detailsOriginal price $9,440.00 - Original price $9,440.00Original price$9,440.00$9,440.00 - $9,440.00Current price $9,440.00| /Save 0% Save % -

Save 0%

Save %

Original price $5,000.00 - Original price $5,000.00Original price$5,000.00$5,000.00 - $5,000.00Current price $5,000.00| /

Save 0%

Save %

Original price $5,000.00 - Original price $5,000.00Original price$5,000.00$5,000.00 - $5,000.00Current price $5,000.00| /Indoor Air Quality Meter - Viasensor G150-01L CO2 0-10,000 PPM + RH

* OPERATIONS MANUAL * * G150 INFO SHEET * Description IAQ analyzer package 0-10,000 CO2 with internal pump and G1.8 RH/T probe.CO2 analyzer design...

View full detailsOriginal price $5,000.00 - Original price $5,000.00Original price$5,000.00$5,000.00 - $5,000.00Current price $5,000.00| /Save 0% Save % -

Save 0%

Save %

Original price $3,410.00 - Original price $3,410.00Original price$3,410.00$3,410.00 - $3,410.00Current price $3,410.00| /

Save 0%

Save %

Original price $3,410.00 - Original price $3,410.00Original price$3,410.00$3,410.00 - $3,410.00Current price $3,410.00| /Indoor Air Quality Meter - Viasensor G150-00L CO2 0-10,000 PPM

* OPERATIONS MANUAL * * G150 INFO SHEET * Description G150-00L CO2 AnalyzerNew CO2 analyzer designed to monitor CO2 for all Indoor Air Quality (IA...

View full detailsOriginal price $3,410.00 - Original price $3,410.00Original price$3,410.00$3,410.00 - $3,410.00Current price $3,410.00| /Save 0% Save % -

Save 0%

Save %

Original price $3,450.00 - Original price $3,450.00Original price$3,450.00$3,450.00 - $3,450.00Current price $3,450.00| /

Save 0%

Save %

Original price $3,450.00 - Original price $3,450.00Original price$3,450.00$3,450.00 - $3,450.00Current price $3,450.00| /Viasensor G100-00L Laboratory Incubator CO2 Analyzer 0-20%

* OPERATIONS MANUAL * * G100 INFO SHEET * Description CO2 Incubator Analyzer, 0 - 20% Viasensor G100 Incubator CO2 Analyzer specifically design...

View full detailsOriginal price $3,450.00 - Original price $3,450.00Original price$3,450.00$3,450.00 - $3,450.00Current price $3,450.00| /Save 0% Save % -

Save 0%

Save %

Original price $3,910.00 - Original price $3,910.00Original price$3,910.00$3,910.00 - $3,910.00Current price $3,910.00| /

Save 0%

Save %

Original price $3,910.00 - Original price $3,910.00Original price$3,910.00$3,910.00 - $3,910.00Current price $3,910.00| /Viasensor G100-10L | CO2 and O2 Incubator Analyzer

* OPERATIONS MANUAL * * G100 INFO SHEET * Description Handheld Incubator Analyzer 0-20% CO2 + 100% O2 With Internal PumpThe New Viasensor G100-10L...

View full detailsOriginal price $3,910.00 - Original price $3,910.00Original price$3,910.00$3,910.00 - $3,910.00Current price $3,910.00| /Save 0% Save % -

Save 0%

Save %

Original price $6,330.00 - Original price $6,330.00Original price$6,330.00$6,330.00 - $6,330.00Current price $6,330.00| /

Save 0%

Save %

Original price $6,330.00 - Original price $6,330.00Original price$6,330.00$6,330.00 - $6,330.00Current price $6,330.00| /Viasensor G200-00PKG N2O Gas Analyzer | Nitrous Oxide Monitor

* OPERATIONS MANUAL * * G200 INFO SHEET * * QUICK START GUIDE * Description Viasensor G200-00PKG The G200 N2O Analyzer is Designed to Safety Check...

View full detailsOriginal price $6,330.00 - Original price $6,330.00Original price$6,330.00$6,330.00 - $6,330.00Current price $6,330.00| /Save 0% Save % -

Save 0%

Save %

Original price $11,173.00 - Original price $11,173.00Original price$11,173.00$11,173.00 - $11,173.00Current price $11,173.00| /

Save 0%

Save %

Original price $11,173.00 - Original price $11,173.00Original price$11,173.00$11,173.00 - $11,173.00Current price $11,173.00| /Dust Opacity Monitor - MRU DM 401 (long)

* DM 401 BROCHURE * Description The dust opacity monitoring system has following major parts: • double pass opacity monitor (transceiver and ref...

View full detailsOriginal price $11,173.00 - Original price $11,173.00Original price$11,173.00$11,173.00 - $11,173.00Current price $11,173.00| /Save 0% Save %

Send Inquiry For More Info

MRU Gas Analyzer

The process of gas analysis requires high precision and industry-specific adaptability. That is why, at Diamond Scientific, we provide a wide range of high-quality and accurate gas analyzers suited for different applications.

Gas Analyzers at Diamond Scientific

Our MRU gas analyzer range includes engine emissions analyzers, O2 and CO2 analyzers, flue gas emission analyzers, compact combustion analyzers, and more. We also offer a variety of biogas analyzers, including the MRU Optima 7 Biogas Analyzer, among other high-performance models.

Our analyzers deliver essential data for maintaining safety, meeting regulatory compliance, and optimizing operational processes. Choosing the right analyzer depends on the specific gases to be measured, required sensitivity, and intended use.

FAQ

Gas analyzers are instruments used to measure the concentration of gases in a sample. Common gases analyzed include oxygen, carbon dioxide, methane, and nitrogen oxides. These tools are vital in industries such as environmental monitoring, industrial manufacturing, healthcare, and research.

A 4-gas analyzer typically measures methane (CH4), hydrogen sulfide (H2S), carbon monoxide (CO), and oxygen (O2). These analyzers are commonly used in confined space monitoring and industrial safety applications.

Gas analyzers allow real-time monitoring of gas levels, support compliance with safety standards, and help detect leaks early. They improve industrial efficiency, reduce equipment needs, and enhance overall workplace safety and environmental compliance.

High-quality gas analyzers can achieve accuracy within ±2% of the measured value, depending on the technology and calibration. Regular calibration and proper maintenance are essential for ensuring ongoing accuracy and performance.

Yes, gas analyzers need regular calibration to align with certified standards. Maintenance may involve cleaning sensors, replacing parts, and verifying operational performance. Refer to the manufacturer's recommendations for optimal care.