Send Inquiry For More Info

Flow analyzers

Flow analyzers are specialized instruments designed to measure and analyze the flow characteristics of fluids (liquids or gases) in various applications. Flow analyzers are used in a variety of industries like manufacturing, research, oil and gas, chemical processing healthcare, and more. In any context where accurate measurement of fluid flow rates is essential for quality control, safety and process optimization, flow analyzers are used.

Flow Analyzers at Diamond Scientific

At Diamond Scientific, we understand the importance of the accuracy and reliability of the measurements displayed by a flow analyzer. By ensuring that the fluid flow is optimal, flow analyzers verify that any given system is functioning correctly. That is why, we provide you with flow analyzers that offer features like accurate measurement of flow rates, temperature, and pressure, along with real-time monitoring, data logging and other advanced functionalities.

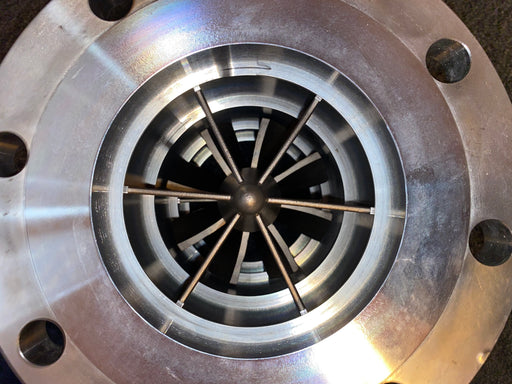

Our Cameron Flanged Flow Analyzers are designed to provide precise flow measurement through a flanged connection to a pipeline or system which is a secure and leak-tight connection for accuracy.

Our Cameron MC-II Direct Mount Flow Analyzers provide information on accumulated flow and flow rate through a local display using information from a turbine flowmeter. These analyzers have proven to be a cost-effective solution.

FAQ

Flow analyzers are devices used to measure and analyze the flow rate of gasses in systems and medical equipment such as flow meters, ventilators, suction devices, anesthesia machines and more. These devices provide accurate and reliable measurements of gas flow rates including volume and pressure.