Description

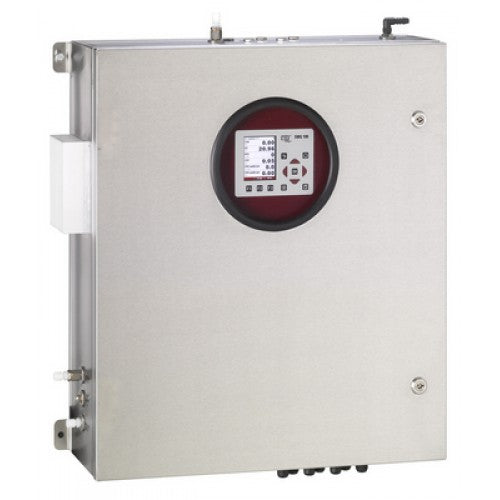

The SWG 100 Biogas-Ex is a rugged, fixed Biogas analyzer with compliance to EN 60079-0, EN 60079-15.

The SWG 100 Biogas-Ex is built for:

-

Biogas (anaerobic digestion) plants. Ethanol plants, pulp & paper plants

-

Cogeneration heat and power engines (CHP)

-

Biomethane plants

-

Landfill gas monitoring and CHP

-

Municipal or industrial waste water treatment plants

-

Coal seam gas sites

Capabilities

|

No Data Available

Not necessarily. When the H2S sensor is exposed to high levels of H2S gas, it is recommended to run the instrument with the gas pump on with ambient air for the same amount of time the sensor was exposed to the high level of H2S. This allows for purging of the instrument before turning the instrument off. Be aware though that continued exposure to levels over 5000ppm H2S will damage the sensor.

Exposure to H2S levels from 2000-5000ppm with moisture will degrade the sensor more quickly. Using filters inline reduces the moisture content of the gas stream entering the instrument.

A common cause for lower than expected gas readings is leakage in the instrument. Perform a leak test by connecting the Condensate Separator Tube to the Pressure Connection 1 Port with tubing.

Perform a leak test as described in the User Manual Optima 7 Biogas. If the leak test fails, check for defective or missing o-rings in the Condensate Separator Tube.

If the user uses the Sampling Probe with sampling lines to take gas readings, place a clean Leak Proof Test Cap on the end of the probe spike. Attach the other end of the sampling line onto the Condensate Separator Tube. Perform the leak test. If the leak test fails, check for defective or missing o-rings in the Condensate Separator Tube and for cracks in the sampling line.

Look closely at the prongs of the thermocouple. The prongs might be dirty. Use a sponge soaked in a 1:3 vinegar/water solution and gently wipe the prongs. Wipe dry with a lint-free cloth or allow to air-dry.

Simultaneously, press the ESC key and the power button then release both keys. You will have to update the Date and Time setting in your instrument afterwards.

No data Available

2. Does it need to be installed under a canopy or shaded area?

The recommended/provided tubing size is as follows (Teflon (PTFE) gas sampling line - 0.16"/0.24" 3.28' (DN4/6mm, 1m length) (MAX 200 meters) @ $12.00/m). SS tubing in the same dimensions is absolutely acceptable and widely used as well. Heat tracing can certainly be helpful, mainly in colder environments where condensate freezing within sample lines is possible/expected. Otherwise the condensate auto-drains that are external to the unit, and when installed as close as possible to the unit will remove 99.9% of moisture before entering the unit. Inside the unit, there is additional condensate removal via a continuous peristaltic pump system.

4. Can you quote a 115VAC power supply?

Absolutely, no problem at all. There is no price change; it is just as simple as leaving a note on the order.

5. Does it require any calibration or carrier gas that we have to provide?

Though it's not a requirement, unless you wish to set-up auto-calibration, we can also provide calibration gas if desired, as it can be helpful to have on hand. Typically, we include one cylinder of a 60%CH4/40%CO2/500ppm H2S mix for units that include an H2S sensor when we quote for the start-up/commissioning or calibration/repair service. But we can quote any mix or cylinder size you may be interested in.